We specialize in fabricating standard and custom air receivers, pressure vessels and pressure vessel heads for a wide range of industries.

ASME Air Receivers

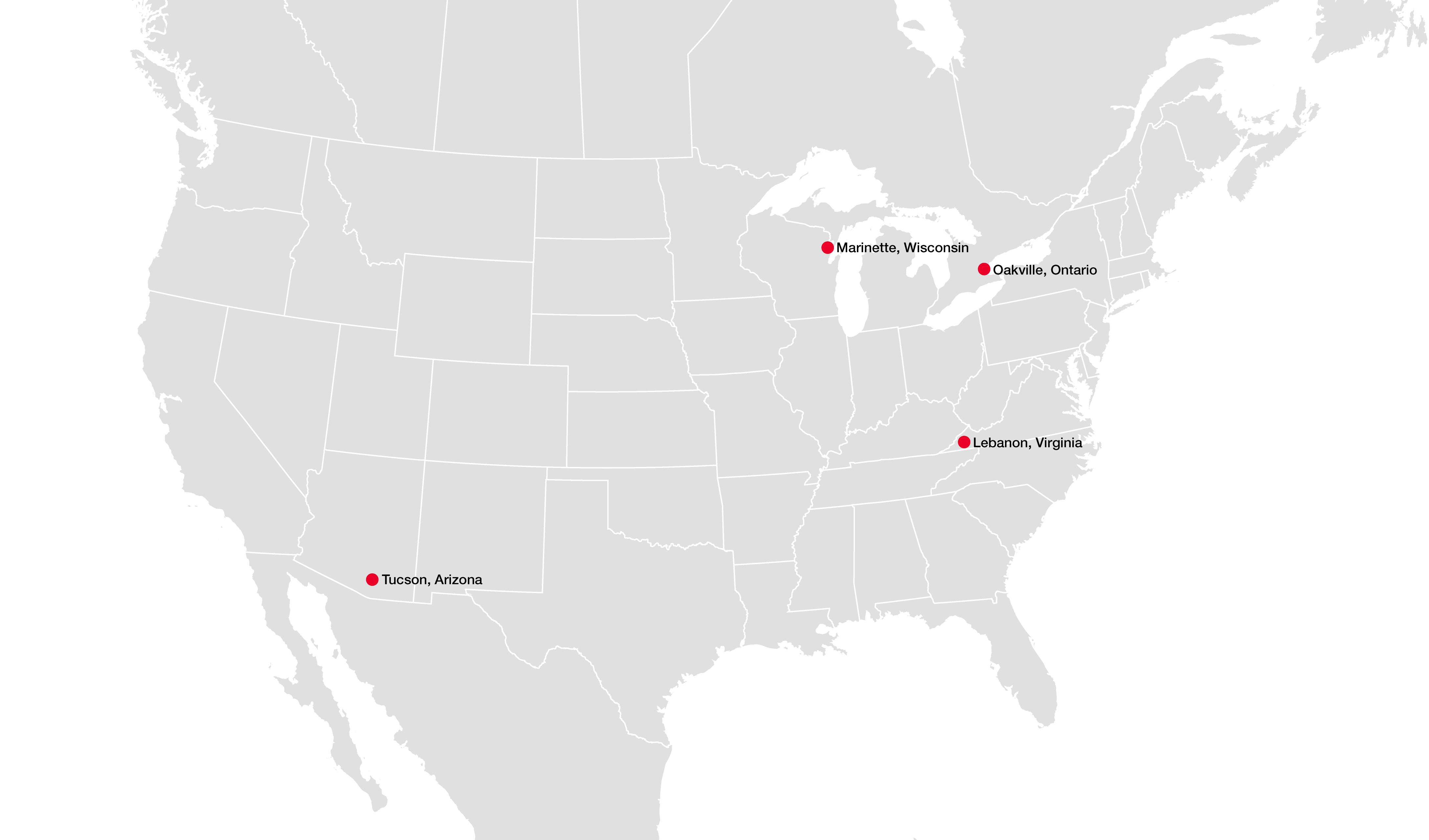

We are proud to be one of the largest suppliers of commercial and industrial ASME Air Receivers in North America, selling more than 100,000 units annually.

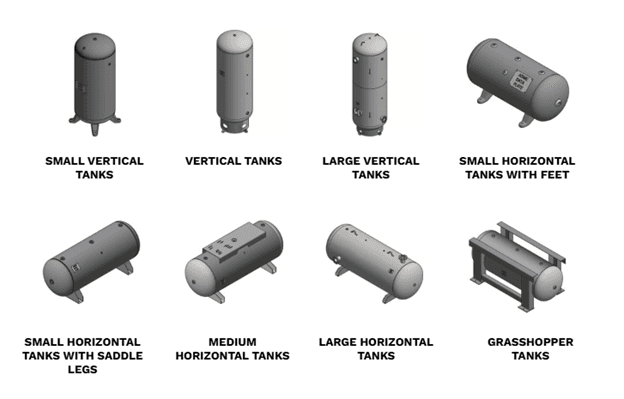

Our offerings include stock vertical and horizontal configurations, from 12 to 5,000 gallons, as well as made-to-order air receiver designs up to 60,000 gallons and engineered-to-order solutions built to your exact specifications.

Industries We Serve

Semi-conductor Manufacturing

We make air receivers, chemical and solvent storage tanks and mixing tanks that are essential for manufacturing memory chips, microprocessors and commodity integrated circuits (CICs).

Water Storage and Purification

Our water and chemical storage tanks are used in potable water storage, treatment, filtration and desalination processes, as well as backwash and well systems.

Clean Energy Manufacturing

Our air receivers, water storage and buffer tanks are used in the temperature control and cooling systems that are essential to the manufacturing of lithium and other clean energy batteries.

Large Air Receivers

These multi-purpose products can be found across the manufacturing, assembly, mining and transportation industries. Uses include automotive and electronic production, rock drilling and tunnelling, railway and aerospace manufacturing and metal fabrication.

Products and Capabilities

Part of our commitment to customer service is extensive choice with a quick turnaround. Offering over 80 standard pressure vessel designs, we’ve got something for everyone and 48 of those standard designs can ship within 24 hours. The rest are part of our QUICKSHIP Program, which is designed to get you products quickly, without sacrificing quality. These options require a four-week lead time.

We also have large crane and welding capacities and can manufacture with many different alloys, allowing us to produce very large, very heavy and very complicated custom vessels that meet your exact needs.

Finishing Options

• Exterior Coatings

• Exterior Powder (Standard Or Custom Colors)

• Exterior Epoxy (Standard Or Custom Colors)

• Interior Powder

• Interior Epoxy NSF & FDA

• Interior Coatings

Accessories

• Safety Relief Device

• Pressure Gauge

• Drain

• Accessory Kit (Includes Safety Relief Device And Pressure Gauge)

Codes & Standards

• ASME Section VIII Div 1 ASME Section VIII Div 2

• ABS Algerian AS1210 CRN CE PED

• DOSH DNV GOST TRCU

• Hazardous Material Regulations (DOT)

• Lloyds MHWL MOM NR13

• SELO USCG

About The Team

With decades of experience manufacturing pressure vessels, we are committed to providing high-quality products and great customer service, which is why we employ over 400 ASME-certified welders, an in-house engineering team and a department specifically devoted to customer care. Whether you’re looking for an ongoing supply program for standard vessels or need support with an engineered-to-spec product, our experienced team is here to help.

Commitment to Quality

We are an ASME Code and ISO 9001:2015-certified manufacturer. We offer specialized testing, on-site inspection and detailed documentation to ensure all our products are of the highest quality and we pride ourselves on maintaining a safe and clean working environment for all our team members.

Project Expertise

With decades of engineering and manufacturing experience, we provide product and solution knowledge for any challenge, giving our customers confidence we will get the job done right.

Learn More About Our Facility in Tucson, AZ

Delivery You Can Count On

We manufacture and ship more than 100,000 pressure vessels for compressed air every year and are strategically located across North America to ensure we can meet the demands or our customers. With our 99.9% on-time delivery score, you can rest assured you will get your products when you need them.